EQUIPMENT AND SERVICES

Known for high quality Magnetic Level Gauges, Magnetostrictive Transmitters, Direct-Reading Level Gauges with armored shield, Sight Flow Indicators, Specific Gravity Analyzers, Point Level Switches, customized solutions.

JOGLER Selected Products

MAGNETIC LEVEL GAUGES

Single or Dual Chambers (JMG) and External Chambers (JXC)

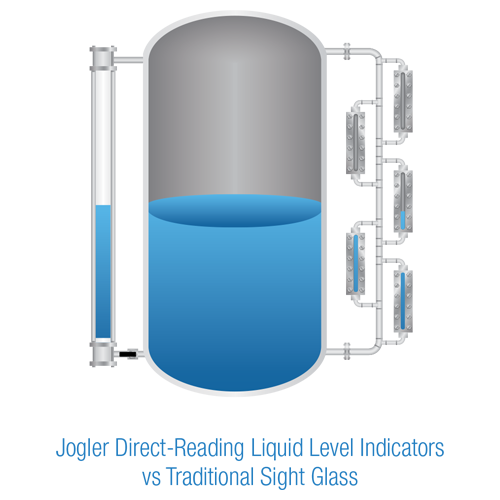

Jogler Magnetic Level Gauges are a safe, economical way to measure and control liquid levels in vessels of any size and shape.

JMG-series Magnetic Level Gauges and JXC-series External Chambers share common features in terms of design, code compliance, weld procedures, and materials. These products are custom designed for each application to provide a true level for any liquid level application.

- Designed to comply with ASME B31.3 or B31.1

- Pressures from FV to 5000 psig (345 Bar)

- Temperatures from -320°F to 1000°F (538°C)

- Fluid SG as low as 0.25

- Interface ΔSG as low as .025

- Wide range of materials

- Indicator visibility to 200 fee

- Lengths up to 50 feet

- Magnetostrictive transmitter option

- Multiple switch options

- High temp and cryogenic insulation

- ASME code U and S certified facility

- PED and CRN certified construction

- ISO 9001 quality system

- Five-year warranty on all parts

STANDARD BARGRAPH

- 3/4” width for maximum visibility

- Flags in various colors

- 1000°F / 538°C with insulation and temp-coat

- Standard or custom rulers 316 SS

- Hermetically sealed, field-repairable tube

WIDE BARGRAPH

- 1.40” width, maximum visibility

- One piece Polycarbonate tube

- Flags in various colors

- -320°F to 700°F / 371°C with insulation & temp-coat

- Standard or custom rulers 316 SS

- Hermetically sealed, field-repairable tube

SINGLE TRACKER

- 3/4” width for maximum visibility

- Orange shuttle indicator

- Standard or custom rulers 316 SS

- Hermetically sealed tube

MAGNETOSTRICTIVE LEVEL TRANSMITTERS

ILT-6000

Direct Tank Insertion Level Transmitter

The ILT-6000 contains a low-profile waveguide that is inserted into a sensor well and float assembly. The sensor well isolates the internal waveguide from the process environment and protects it from excessive process conditions. This provides an additional safety barrier for the operator. The major benefit is the transmitter and waveguide can be removed from sensor well without shutting the process down for field checking / calibration.

- Direct Insertion into the process media (Sumps, Tanks, Bridles, Stilling wells, etc.)

- Accuracy 0.01% full scale, LCD display, 4-20 mA with HART

- Similar applications to guided wave radar but with no need to consider Dielectric Constant

- Field-replaceable electronics module, sensor wire assembly

DIRECT-READING

LIQUID LEVEL / LIQUID FLOW INDICATORS

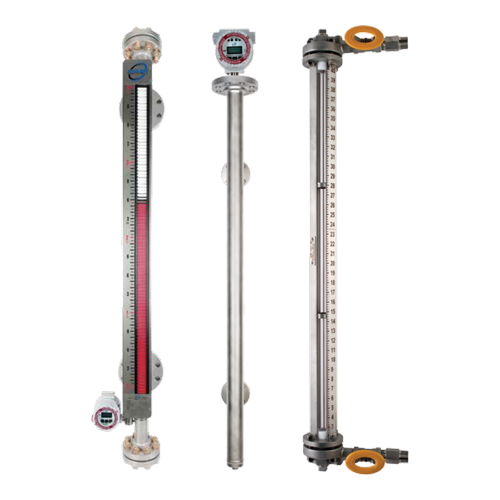

DIRECT-READING LIQUID LEVEL INDICATORS

- LS series Single-Tube Armored Level Indicator

- ULSS series Teflon Lined Single-Tube Armored Level Indicator

- LT series Tube-N-Tube Armored Level Indicator

- ULTS series Teflon Lined Tube-N-Tube Armored Level Indicator

Model JS-10/JS-30 Series

Manetic Level Switch

For Magnetic Liquid Level Indicators

Description

The Jogler JS-10/JS-30 Series switches are magnetically actuated point level switches. The JS-10 (1 amp) and JS-30 (3 amp) can be configured as a SPDT or DPDT and are available in a “flying lead” configuration (no enclosure), an epoxy-coated Aluminum enclosure, or a 316 stainless steel enclosure. The JS-10 is a low power switch best suited for DCS or PLC inputs. The JS-30 is a high power switch used to actuate larger relays and solenoid valves. The JS-10/JS-30 switches re non-intrusive level switches that require no contact with the process fluid and have no wetted parts.

Technology

The JS-10/JS-30 Series contain 1 or 2 form C bi-stable latching switches. The switches consist of a magnetically actuated reed switch and bias magnet. Reed switch contains precious metal contacts hermetically sealed in an inert gas atmosphere sealed with a glass-to-metal bond. The bias magnet holds the switch in its last state, allowing it to maintain its state even in high-vibration environments. The hermetically-sealed contacts ensure safe operation even in hazardous environments.

Standard Features

- Magnetically actuated, hermetically sealed, bi-stable latching switch

- No process piping or valves required

- Easy mounting with infinitely adjustable setpoint

- Hermetically sealed magnetic reed switch. Latching bias magnet maintains state in high-vibration environments

- Available with flying leads (no enclosure), Epoxy-coated Aluminum enclosure, or a Stainless Steel Enclosure

- Extended operation in extreme environments