EQUIPMENT AND SERVICES

BRUIN PUMPS are your Direct Texsteam Replacement.

BRUIN Selected Products

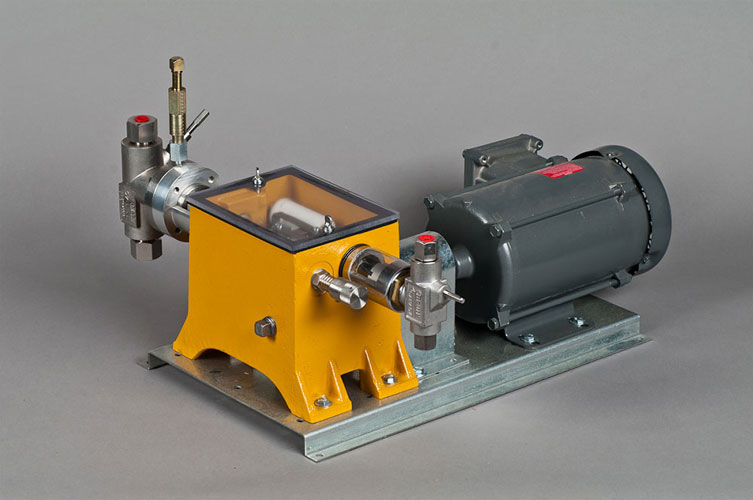

BR4300

Electric Driven

Direct replacement of Texsteam Pumps

The Bruin BR4300 Chemical Injector Pump is a gear driven, positive displacement, plunger type pump that utilizes a rotary electric or hydraulic power source. An integral worm gear drive, available in three standard gear ratios, along with six available plunger sizes, provides a wide selection of volumes up to 1232 Litres per day with a 1” head and discharge pressures up to 5000 psig with a 3/16” head. Each pump is capable of supporting a single or double head configuration with the ability to link multiple pumps together, allowing up to eight heads to be driven by a common motor. The BR4300 comes standard with a micrometer type stroke adjustment for each head allowing independent adjustment.

- Adjustable stroke length (0 – 100%), plunger sizes (3/16”, 1/4”, 3/8”, 1/2”, 3/4” & 1”) and gear ratios (100:1, 50:1, 25:1) provide an adjustable volume output up to 1232 Litres per day per head.

- Single head, double head and multiplex configurations available. Supports different size plungers on a single gearbox.

- Stroke length adjustable during operation.

- 12V, 115V and 230V XP CSA electric motors and hydraulic drive motor configuration available.

- Designed for ease of operation and maintenance under varied pumping applications.

- Conversion for handling of various chemicals is easily accomplished by the change out of the packing set and fluid end seals.

BR5100

Pneumatically Driven

Direct replacement of Texsteam Pumps

The Bruin BR5100 Chemical Injector Pump is a single acting, positive displacement plunger type pump. Equipped with a spring return, automatic switching mechanism and powered by pneumatic pressure acting against a diaphragm, it is capable of operation with supply pressures as low as 2 psig (35 psig max.) and available in 4 plunger sizes. The BR5100 can handle output volumes up to 137 Litres per day with a 1/2” head and discharge pressures up to 6000 psig with a 3/16” head. Volume is controlled based on plunger size, the stroke length selection and the speed of the pump via a speed control valve. Maximum discharge capability is governed by the packing selection, and discharge pressure can be controlled with the supply pressure via a regulator.

- Adjustable speed (0 – 30 spm) and plunger sizes (3/16″, 1/4″, 3/8″ & 1/2″) provide an adjustable volume output up to 137 Litres per day maximum.

- Air distribution system provides greater control of the stroke rate and injection rate without stalling.

- Micro Switch system provides oilless operation.

- Contoured diaphragm plate improves diaphragm life.

- Low supply pressure model allows for operation with pressures as low as 2 psig (dependant on discharge pressure and pump set up).

- Conversion for handling of various chemicals is easily accomplished by the change out of the packing set and fluid end seals.

BR5000

Our Pneumatic Workhorse Pump

The Bruin BR5000 Chemical Injector Pump is a single acting, positive displacement plunger type pump. Powered by pneumatic pressure acting against a diaphragm, equipped with a spring return, automatic switching mechanism and available in 6 plunger sizes. The BR5000 can produce output volumes up to 2150 Litres per day with a 1 ¼” head and discharge pressures up to 12000 psig with a 1/4” head. Volume is controlled based on plunger size, stroke length selection, and the speed of the pump via a speed control valve. Maximum discharge capability is governed by the packing selection and discharge pressure can be controlled with the supply pressure via a regulator with a 1” head and discharge pressures up to 3000 psig with a 3/16” head.

BR1200

Beam Driven Chemical Injection

The Bruin BR1200 Chemical Injector Pump is a beam driven, positive displacement, plunger type pump that was designed specifically for operation on a beam pumped well. It is powered by walking beam, rod line, or rocker arm movement via direct connection with a length of nominal pipe or wire line. The unit pumps on the upstroke of the beam action and returns to its set position on the downstroke. Single or double head configurations available in 6 different plunger sizes, 3 stroke length settings and a ratchet mechanism with an adjustable engagement of 1 to 20 teeth. The BR1200 can produce output volumes up to 60 Litres per day with a 1” head and discharge pressures up to 3000 psig with a 3/16” head.

BR2400

Electric Displacement Plunger

The Bruin BR2400 Chemical Injector Pump is an electric driven, positive displacement plunger type pump. It’s powered by a C-faced motor mounted onto a gear reducer; available in 30 or 60 strokes per minute. Available in 4 plunger sizes, the BR2400 can handle output volumes up to 3332 Litres per day per head with the 1 ¼” head and discharge pressures up to 4000 psig with the ½” head. Volume is controlled, based on plunger size selected and the speed of the pump based on the gearbox size, via a stroke length adjustment that can be adjusted while the pump is running. Maximum discharge capability is governed by the plunger size selection and the packing selection

BR6000

Positive Displacement Plunger

The Bruin BR6000 Chemical Injector Pump is a single acting, positive displacement plunger type barrel pump. Powered by pneumatic pressure acting against a piston, equipped with a spring return and standalone timer. The BR6000 can produce output volumes up to 204.2 Litres per day with a 1/2” plunger and discharge pressures up to 3000 psig with a 1/4” plunger. Volume is controlled based on plunger size, stroke length selection, and the speed of the pump via a timer. Maximum discharge pressure capability is governed by the seal selection and discharge pressure can be controlled with the supply pressure via a regulator.

ECP

Environmental Containment Package

The Bruin ECP is a self-contained package that houses the chemical injection pump, chemical tank and all tubing, gauges, and accessories. Full system is enclosed, eliminating collection of rain, dirt or trash into the secondary containment, maintaining its full capacity while eliminating costly clean outs resulting from natural collection of these materials. Entire system is fully supported with metal frame and fully assembled allowing easy setup and relocation if required. The Bruin ECP can easily be moved without disassembling the components and fits into the bed of a standard truck box.